Lorem Ipsum, dizgi ve baskı endüstrisinde kullanılan mıgır metinlerdir.

Lorem Ipsum, dizgi ve baskı endüstrisinde kullanılan mıgır metinlerdir.

Lorem Ipsum, dizgi ve baskı endüstrisinde kullanılan mıgır metinlerdir.

Rigid polyurethane is used in many applications in the field of heat and cold protection due to its excellent thermal insulation properties. It provides the best available thermal performance at the lowest thickness, which makes it the most ideal material for bee hives.

Polyurethane hives provide effective thermal insulation helping keep the colony warm in the winter and cool in the summer. This ensures that seasonal changes do not affect the bees’ interior habitats.

The thermal insulation provided by the rigid polyurethane creates an even temperature in the hive, preventing condensation which could drip down onto the winter cluster and kill the colony.

Rigid polyurethane keeps the internal hive temperature far more constant than wood, enabling the colony to manage the internal hive environment with minimal effort. Therefore, the bees spend less time and energy keeping the hive cool during the summer or warm during the winter, using this time and energy on nectar processing and brood rearing instead, which will result in an increase in honey production.

Polyurethane hives ensure that the bees overwinter in good health and without losses, consuming less honey. Moreover, the colony coming strong out of the winter builds up their peak populations earlier in the spring and takes advantage of maximum nectar flow.

Polyurethane hives are extremely resistant to abrasion and wear caused by atmospheric agents, water, solvents, and chemicals. Wood rots, plastic warps, metal rusts, but polyurethane stands the test of time even under the toughest environmental conditions.

.png)

The fresh air coming in from the vent slots at the bottom rises to the top of the hive through the screen floor and the vent slots located around the feeder and then eventually leaves through the vent slots on the top cover.

.png)

The hive bodies are manufactured using reaction injection molding (RIM) technology which allows to mold parts as a single piece rather than molding several parts and assembling them. One-piece molded hive bodies prevent not only heat losses which may otherwise be caused by the joint gaps, but also fungus spores which can remain in the joint gaps

Polyurethane hives are designed to be easily transported. While the recesses on the top covers enable the hives to be safely stacked up on top of each other, the strapping grooves allow you to securely attach the hives to the vehicle, preventing them from slipping off during transportation.

The latches on the sides provide stability by fixing the hive bodies together. The hive entrance has a hinged landing board that can be closed in transit, which prevents bees from coming out of the hive.

Rigid polyurethane provides excellent resistance to many common chemicals and solvents. Hence, polyurethane hives are capable of being sterilized by using disinfectants such as washing soda, sodium hypochlorite or household bleach in case of any disease, and then they can be washed off without leaving any residues as the rigid polyurethane does not absorb liquids.

Varroa mites are the most serious threat to bees, resulting in the death of the entire colony. Polyurethane beehives have a screened bottom board with a drawer,helping reduce the varroa populations of the colony. Varroa mites falling on the drawer through the screen floor are unable to reintegrate themselves into the colony. The screen floor also enables debris to fall out of the hive, saving the bees the effort of having to remove it. Beekeepers can check on the health of the colony by monitoring the drawer.

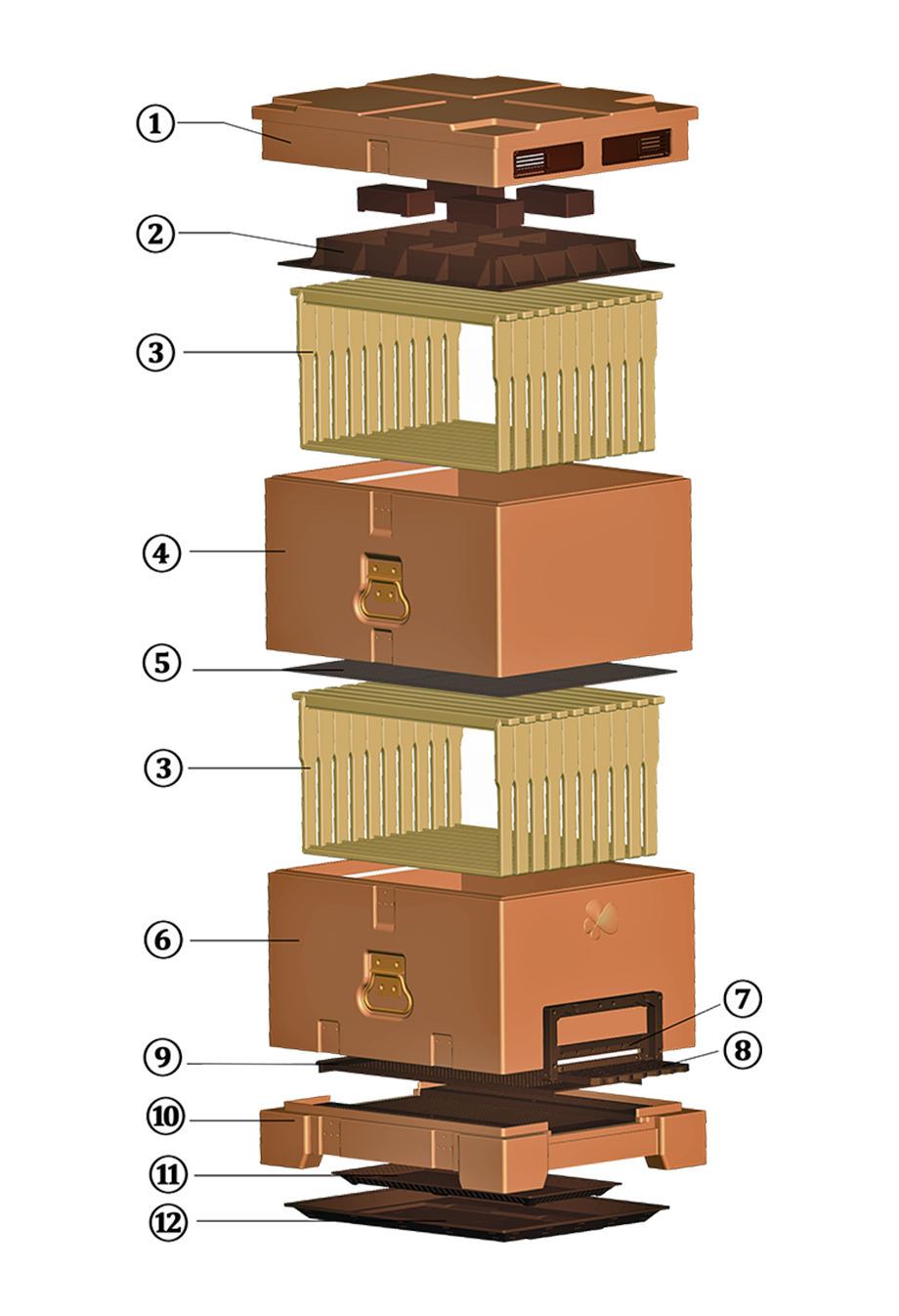

Polyurethane hive includes all components below:

① Top Cover

② Top Feeder (3 lt of total capacity)

③ 20 Frames

④ 1 Super

⑤ Queen Excluder

⑥ 1 Brood Box

⑦ Entrance Reducer

⑧ Hive Entrance

⑨ Pollen Trap

⑩ Screened Bottom Board

⑪ Pollen Tray

⑫ Drawer

• It is designed base on Langstroth beehive dimensions.

• The top cover, brood box, super, bottom board and frames are made of rigid polyurethane, and the other parts of the hive are made of polypropylene. Wooden frames are also available.

• The thickness of the hive bodies is 30 mm.